We are glad to present you the report from the Opel plant in Russelsheim. Adam Opel opened a factory producing stitching machines in 1863 in the German city of Russelsheim. Today

it's the place of the oldest and largest auto plant in the world. 16

000 people are employed and 180 000 cars are annually produced by the

plant.

Employees move by bicycles, you may see a bicycle lane to the left.

It's the place where they deliver metal used for car bodies details. In

fact, Insignias ans Astras are produced at the plant, but in the

plating department they make workpieces for all models which are further

transported to other plants.

It's the biggest plating department that belongs to Opel.

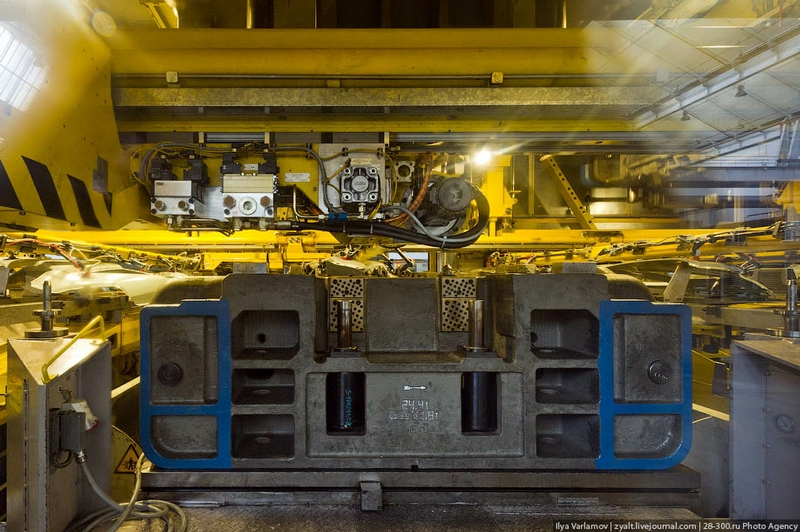

All the shop is occupied by huge press machines. When they work the floor is vibrating like at a light earthquake.

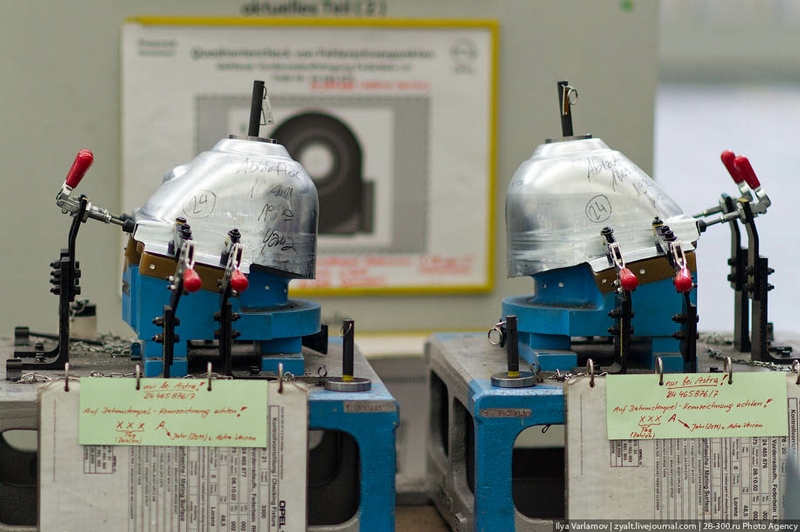

Moulds

Moulds are marked in different colors depending on a model.

This machine makes up to 20 small moulds a minute.

Model stand. Some details are chosen from each batch and compared to the models.

A new press machine. It costs 40 million euros! Its weight - 6500 tons. It may press one side of a car at a time.

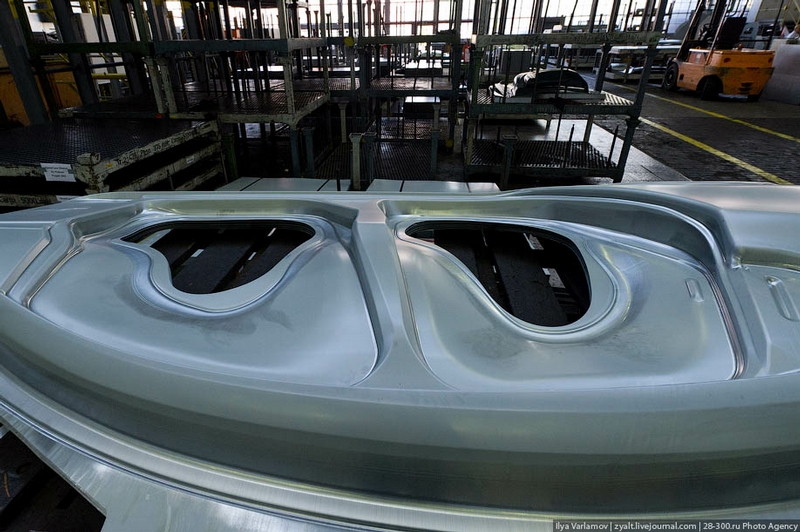

The side of a three-door Astra is coming.

Excess metal is cut off.

And then it is sent to the assembly belt line.

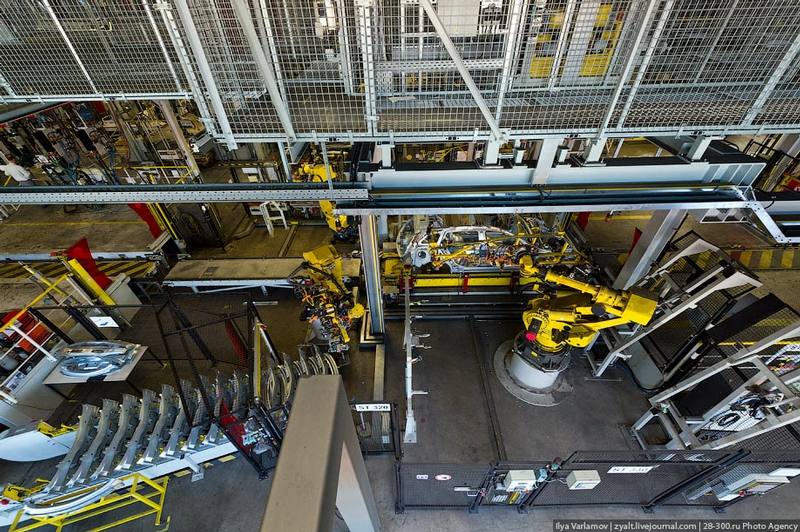

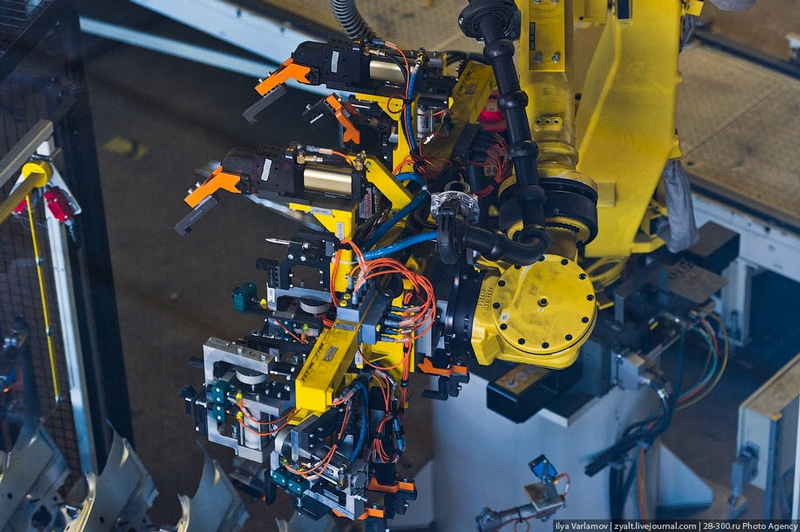

In the welding workshop everything is automated, that's why it may be viewed only from above.

Workshop works in two shifts. There are 200 workers in each shift. At

body assembly 700 robots are used, each of them costs 100 000 euros.

There is no place for a human where robots operate. If someone enters this zone, production will pause.

Roofing is welded with a laser. Opel Insignia has 4500 welded spots.

The bare body weighs 400 kg, painting takes 8 kg of paint and lacquer.

All in all 16 000 employees work at the plant. 7000 of them are directly working on the assembly, 5000 - management.

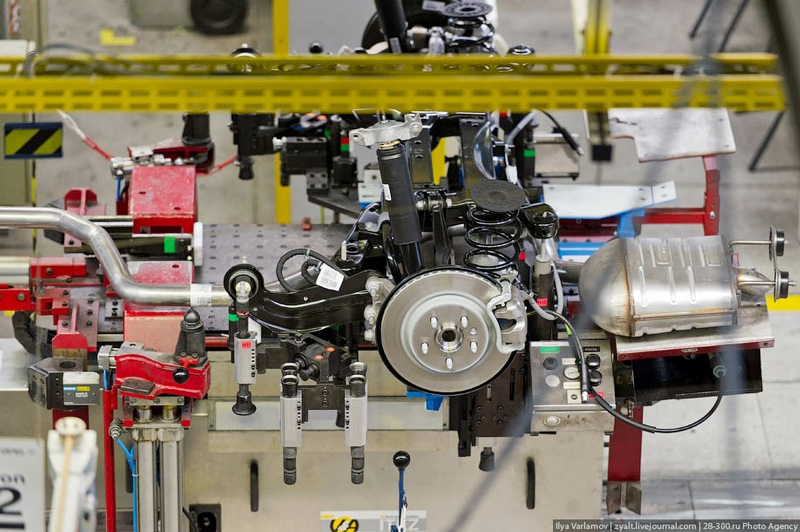

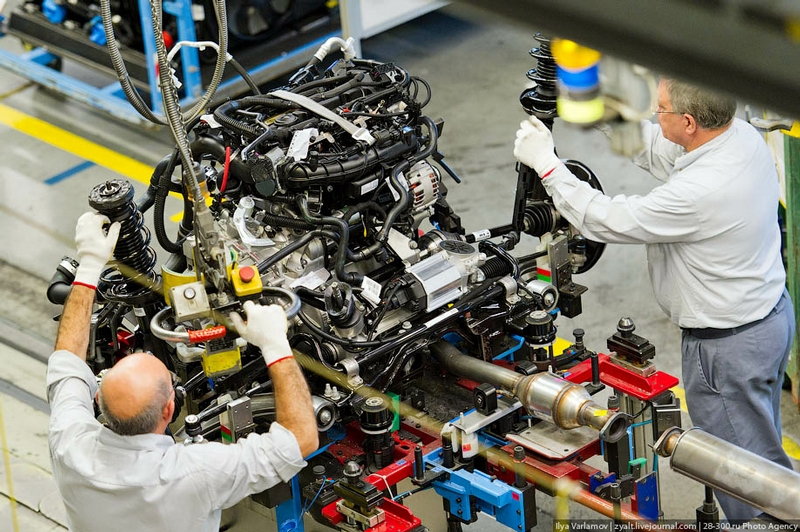

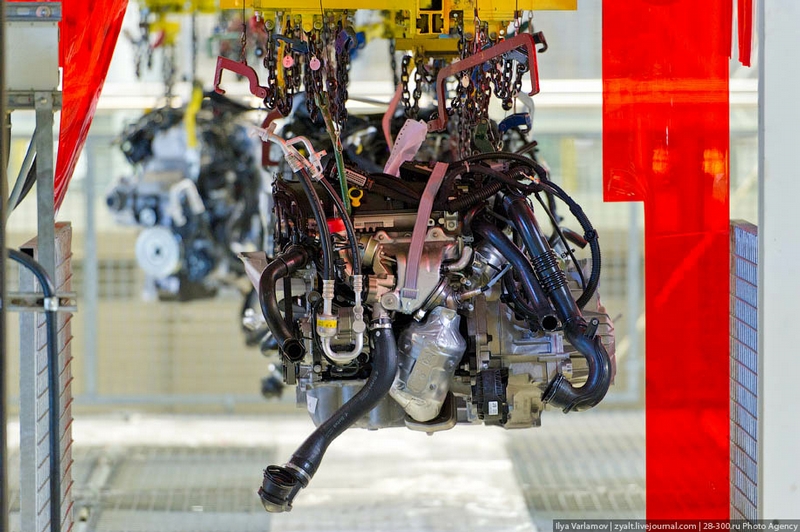

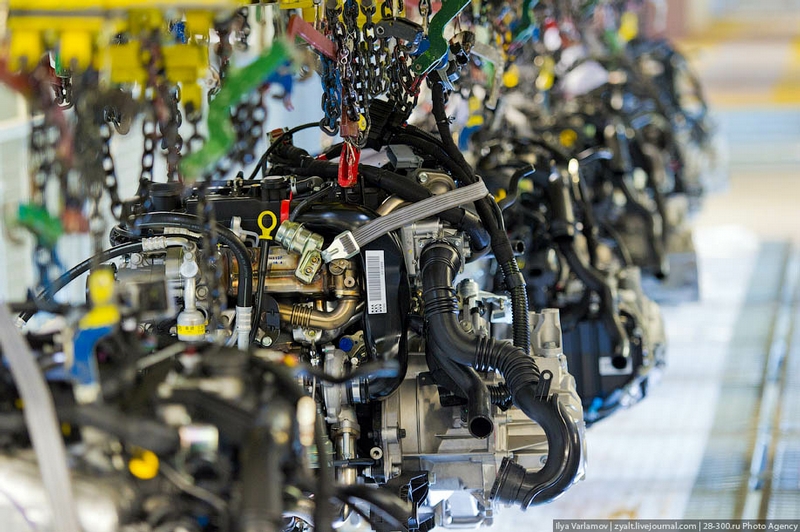

All engines are different

40 types of motors are delievred to the conveyor. Each motor finds its car - it is controlled by a special computer.

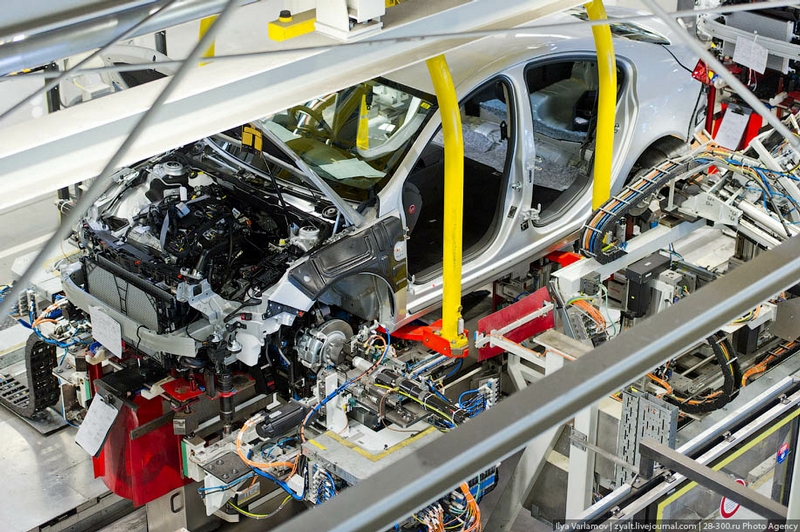

The process when an engine connects with a body is called "wedding ceremony".

Employees work in groups, 5 of them in each group. 65 seconds is the

time when a worker has to fulfil some stage of the work. If he can't the

conveyor stops.

9 different car models may be produced on one conveyor. All cars on the

conveyor are different as you may see. Assembly is controlled by

computers.

Almost ready car

When the assembly is over the car should be tested in some various

ways. For example it's poured over with water in a special cell to check

the hermeticity. Then it has to overcome an obstacle course. The driver

hears how the car behaves on uneven surfaces.

New three-door Astras

Amperas

Ready cars are taken away by railway from the plant.

And this is a hall where cars' destiny is shaped. Different models are discussed here by teams from different countries.

via zyalt

0 comments:

Post a Comment